Discovering the Right Provider for Welding Inspection Madison: Secret Considerations

Discovering the Right Provider for Welding Inspection Madison: Secret Considerations

Blog Article

Recognizing the Basics of Welding Evaluation to Make Sure High Quality and Safety And Security

In the realm of contemporary design, welding evaluation stands as a keystone for making sure both the top quality and security of architectural creations. What are the nuances of these examination techniques that make them crucial for preserving architectural stability?

Relevance of Welding Evaluation

In the realm of commercial fabrication, the significance of welding examination can not be overemphasized. Welding evaluation plays an essential function in ensuring the honesty, safety and security, and longevity of welded structures. Given the diverse applications of welding in industries such as construction, automobile, aerospace, and shipbuilding, the demand for rigid high quality control procedures is critical. Appropriate assessment guarantees that welds satisfy defined codes and requirements, which is vital for avoiding structural failures that could lead to disastrous effects.

The process of welding inherently involves complex variables, including temperature level, material properties, and environmental problems, all of which can affect the high quality of the weld. An extensive evaluation determines flaws such as fractures, porosity, and insufficient combination, which can jeopardize the toughness and integrity of the weld. By discovering these issues early, corrective activities can be taken, therefore lowering the threat of failing and linked costs.

Additionally, welding assessment adds to governing compliance, as numerous industries are governed by rigorous safety requirements and guidelines. Failing to adhere to these regulations can lead to legal liabilities and monetary charges. Ultimately, welding inspection not just safeguards physical frameworks but additionally safeguards human lives and supports industry track records.

Secret Welding Assessment Methods

Although welding examination is crucial to making certain the top quality and safety of welded structures, it is the specific techniques used that establish the efficiency of the evaluation process. Secret welding evaluation techniques can be generally classified into non-destructive screening (NDT) and devastating testing. Non-destructive screening methods such as aesthetic examination, ultrasonic testing, radiographic screening, magnetic fragment testing, and fluid penetrant testing are mostly utilized to assess the residential or commercial properties of a weld without creating damages. Visual assessment is commonly the initial step, entailing a detailed evaluation of the weld's surface area for defects like fractures or porosity.

Magnetic particle testing and fluid penetrant testing are surface area inspection approaches used to situate surface and near-surface imperfections. These comprehensive assessment methods make sure that welds satisfy industry criteria and security demands, therefore making sure structural honesty and efficiency.

Duty of Certified Assessors

Licensed assessors play an essential role in the welding evaluation process, ensuring that all welds adhere to stringent market standards and security policies. Their experience is crucial in identifying defects or irregularities that may compromise the architectural stability of a weld. By diligently analyzing each weld, accredited assessors aid stop potential failures that can bring about hazardous crashes or expensive fixings.

To end up being certified, examiners have to undergo strenuous training and screening, which familiarizes them with various welding methods, materials, and testing approaches. This extensive understanding enables them to review weld top quality go to this site properly and make educated judgments concerning their safety and integrity. Qualified inspectors are efficient in analyzing specifications and plans, guaranteeing that the welding work straightens with the project's design needs.

An essential part of their role is to document their searchings for thoroughly, offering a comprehensive record of the inspection process. This documents is vital for traceability and liability, functioning as an official document of compliance with market standards. Licensed inspectors likewise play a crucial role in facilitating communication in between task stakeholders, offering recommendations and understandings to improve welding methods and outcomes. Their contribution is crucial in preserving high levels of top quality and security in welding procedures.

Devices Used in Welding Inspection

Welding assessors rely upon a selection of specialized tools to execute their duties properly, making certain each weld fulfills the required standards. Among these tools, visual assessment aids like amplifying glasses and mirrors are essential, enabling examiners to very closely examine welds for surface area problems such as fractures, porosity, and undercut. Calipers and fillet weld evaluates are crucial for measuring weld dimensions to confirm conformity with style specifications.

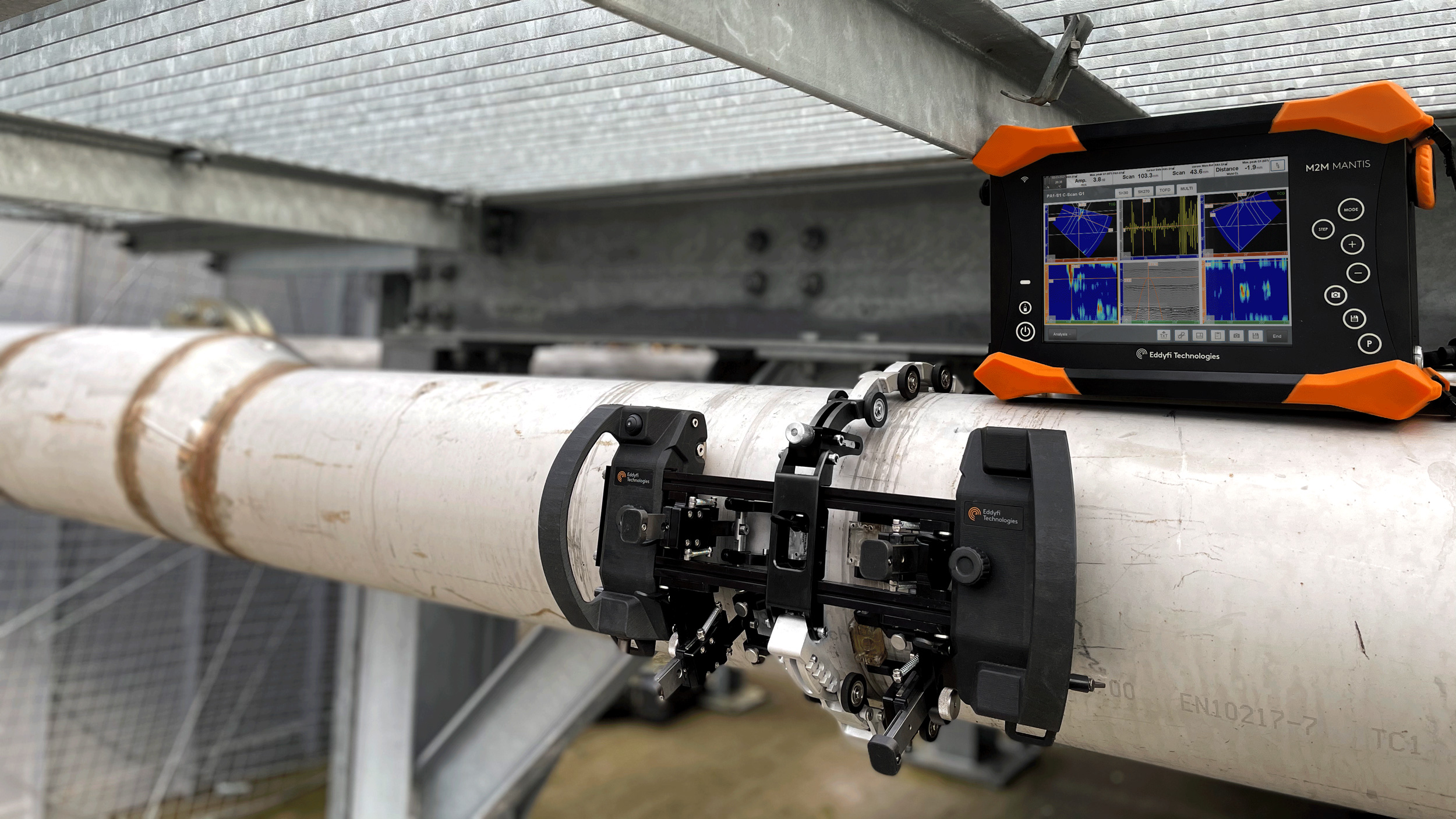

Advanced tools extend past visual aids, consisting here of non-destructive screening (NDT) devices. Ultrasonic testing gadgets are pivotal in detecting subsurface problems, utilizing audio waves to reveal internal stoppages without endangering the weld's honesty. Radiographic screening utilizes X-rays or gamma rays to record photos of a weld's interior, highlighting possible defects.

Magnetic bit testing is another vital tool, especially for finding surface area and near-surface stoppages in ferromagnetic materials. By applying magnetic areas and ferrous particles, examiners can recognize defects that could otherwise be invisible.

Dye penetrant inspection is usually used for non-ferrous products, offering a contrast-enhanced aesthetic check for surface-breaking defects. Welding Inspection Madison. With each other, these devices enable welding inspectors to adequately assess weld quality, guaranteeing safety and dependability in various applications throughout markets

Making Sure Architectural Honesty

Welding procedures have to stick to well-known criteria and codes, such as those defined by Discover More Here the American Welding Culture (AWS) or the International Company for Standardization (ISO) These standards make certain that the welds can hold up against operational tensions and ecological elements. Certified and accredited welders play a vital duty in this procedure, as their competence makes certain that techniques are used properly, minimizing issues such as fractures, porosity, and insufficient fusion.

Post-weld inspection is another important component of confirming architectural honesty. Non-destructive screening (NDT) approaches, including ultrasonic screening and radiographic screening, are utilized to discover subsurface imperfections without endangering the bonded structure. These evaluations validate that the welds meet the needed quality requirements, giving guarantee of their toughness and integrity. Inevitably, ensuring architectural integrity in welding not only safeguards human lives yet likewise secures financial investments and improves the durability of engineered structures.

Verdict

The principles of welding evaluation are essential for preserving the top quality and safety of welded structures. The usage of specialized tools further boosts the evaluation procedure, inevitably safeguarding human lives and extending the life-span of welded building and constructions.

Welding inspection plays a crucial role in guaranteeing the stability, safety, and long life of bonded structures.Although welding assessment is essential to ensuring the top quality and safety of welded structures, it is the certain methods used that identify the performance of the evaluation process. Secret welding assessment techniques can be broadly categorized into non-destructive screening (NDT) and harmful screening.Qualified inspectors play a critical role in the welding examination procedure, ensuring that all welds comply with stringent sector criteria and safety and security laws.The basics of welding inspection are vital for preserving the high quality and safety of welded structures.

Report this page